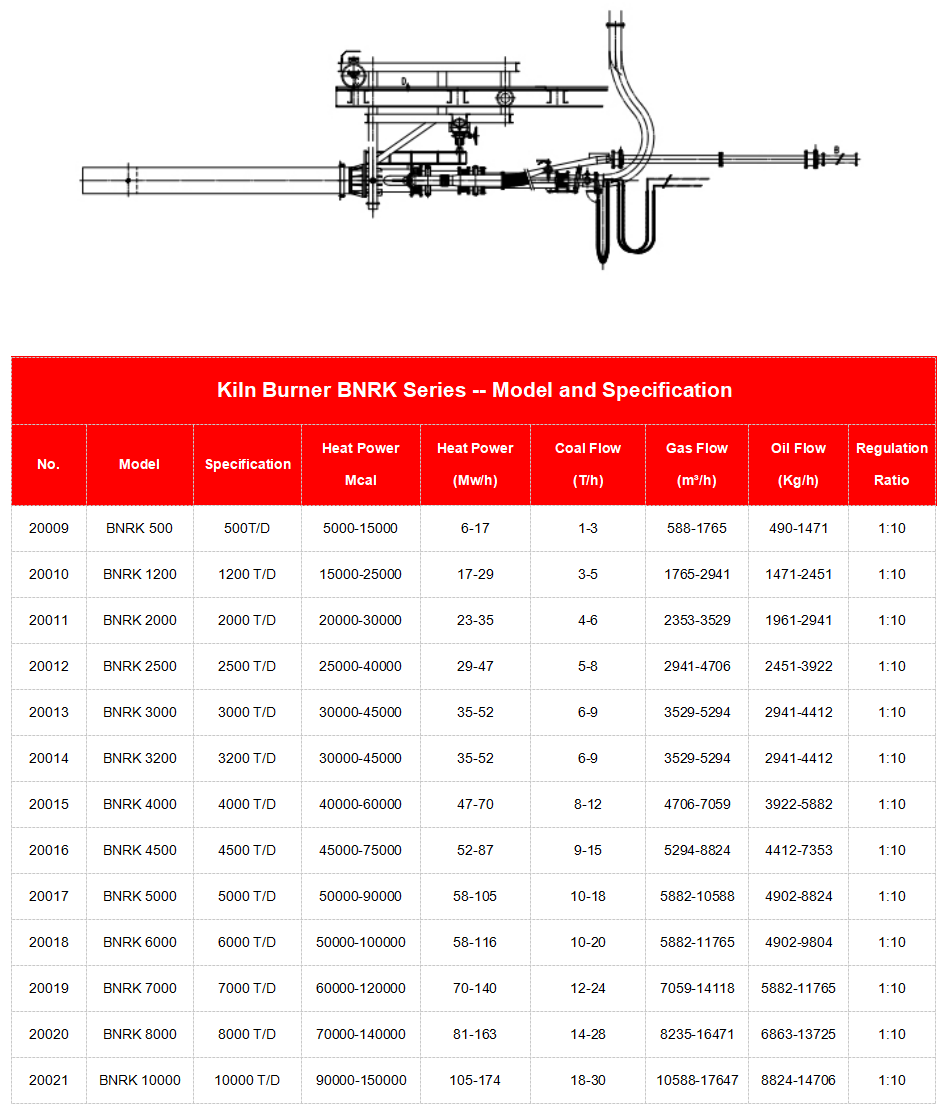

Rotary kiln burners

Advantages of multi-channel (rotary kiln) burner:

(1) Increase the mixing of pulverized coal and combustion air, increase the combustion rate, and the fuel burns completely and stably.

(2) Increase the means of adjusting the air volume and wind speed of each channel to make the flame shape and temperature adjustment flexible and convenient, suitable for clinker calcination.

(3) The burner has a long service life.

(4) Protect the kiln lining material and prolong the service life of the lining.

(5) Stabilize clinker quality and increase system output.

(6) Simple structure, convenient maintenance and replacement, reducing the operating time of the system due to burner failure.

(7) Keep the amount of primary air as low as possible, increase the use of high-temperature secondary air, and increase the utilization rate of heat recovery from clinker.

(8) The system resistance is as low as possible to reduce the power consumption of the primary fan.

(9) It can reduce the emission of harmful substances (especially NOx).

(10) Low-grade fuels can be used to strengthen the comprehensive utilization of fuels, and lower equipment prices and maintenance costs.

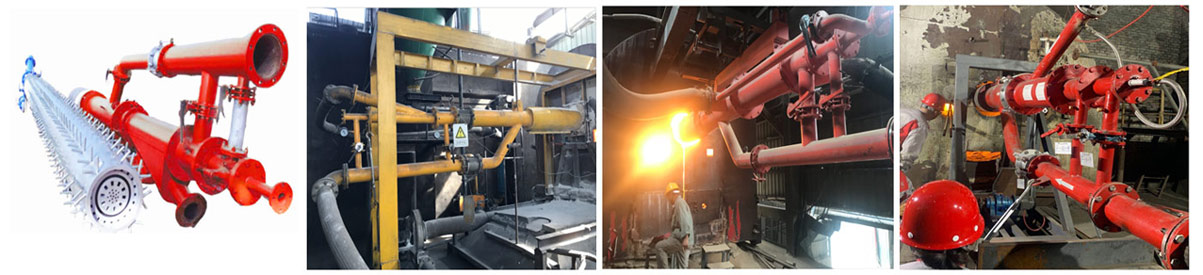

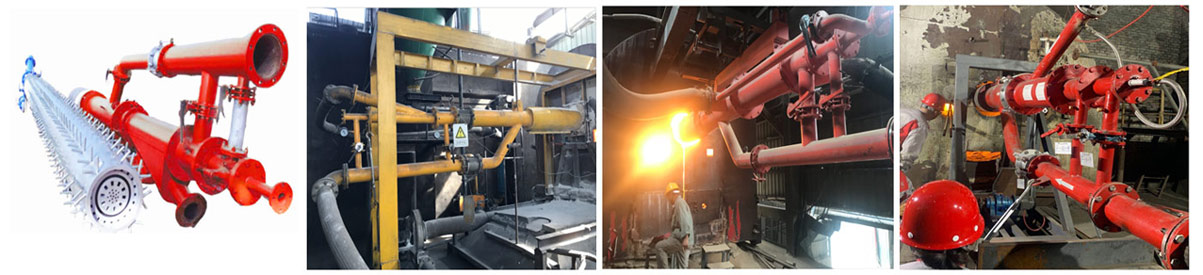

Rotary kiln burner performance:

Power range: 200~20000kW

Single burner adaptation: 500~10000t/d production line

Multi-channel applicable fuel:

•Pulverized coal, blue charcoal

•Natural gas, liquefied gas, coal gas, light hydrocarbon gas, etc.

•Light oil, heavy oil, residual oil, mixed oil

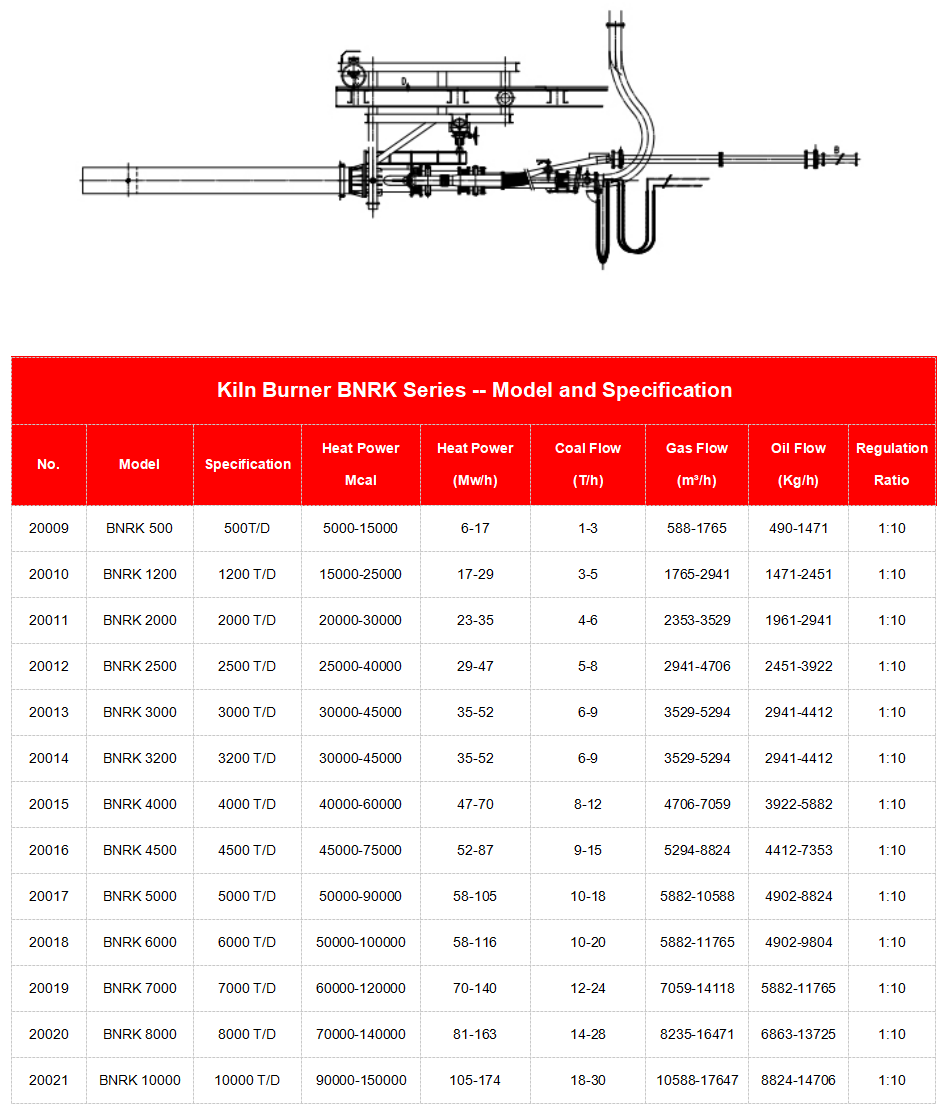

Rotary kiln burners are mainly used in:

Various types of kilns such as cement kilns, pellet kilns, lime kilns, lithium kilns, magnesia kilns, alumina kilns, chromium salt kilns, beneficiation kilns, etc. in the building materials, metallurgy, chemical, electric power and other industries.

According to the process requirements, it can be designed as two-air, three-air, four-air, and five-air burners.