- E-mail: [email protected]

- POffice Add:13th Floor, Building 16, National University Science Park,Zhengzhou,Henan,China

- Factory Add:No. 33 Xinhua Road,Xinmi,Henan,China

- +0086-156-3978-1876

- [email protected]

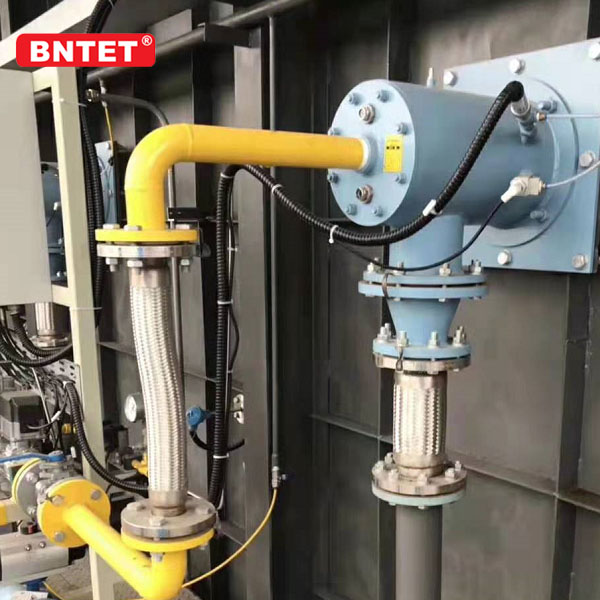

Under normal production conditions, the treatment process of the burner equipment of the stenter setting machine can be summarized as: rolling car, Upper overfeeding, lower overfeeding, main chain, brush, cloth out, and cloth drop. The so-called stenter process actually mainly refers to applying a certain tension to the weft direction of the fabric with the help of the burner equipment of the stenter setting machine. In this way, after receiving the force, the fabric can effectively remove the defects of uneven cloth edge, weft skew, and uneven width caused by the large warp tension during the pre-processing, dyeing, printing and other processing processes. As for the setting process, it is to properly set the tension of the burner equipment of the tenter setting machine, so that the fabric is heated to the required temperature and maintained for a certain period of time under the proper tension condition, so that the fiber molecular chain can be readjusted in the new position. Then let it cool down at a certain speed, so as to fix the state of the fabric after the heat treatment. In other words, the use of the burner equipment of the stenter setting machine can cleverly eliminate the original wrinkles on the fabric and prevent the generation of new wrinkles. In the transmission system of the low-temperature combustion machine, the whole machine mainly consists of 7 synchronous transmission units, 4 circulating fans (8-chamber drying room) and 2 exhaust fans. About the technical requirements of the stenter setting machine burner: First of all, in the actual operation process, in order to ensure a good processing effect, the speed and position of the left and right main chains of the stenter setting machine burner equipment need to be synchronized to avoid fabric weft deviation. Secondly, 10-segment width control, the amplitude modulation accuracy should be controlled within ±2mm. In addition, in the process of processing the burner of the stenter setting machine, it is also necessary to strictly control its temperature and tension in accordance with the process requirements. This is because temperature and tension are two key parameters in the shaping process. Reasonable control of these two parameters will help improve the treatment effect of the burner of the stenter setting machine. ! If you are interested in low temperature burners, please contact us for a quote!

Under normal production conditions, the treatment process of the burner equipment of the stenter setting machine can be summarized as: rolling car, Upper overfeeding, lower overfeeding, main chain, brush, cloth out, and cloth drop. The so-called stenter process actually mainly refers to applying a certain tension to the weft direction of the fabric with the help of the burner equipment of the stenter setting machine. In this way, after receiving the force, the fabric can effectively remove the defects of uneven cloth edge, weft skew, and uneven width caused by the large warp tension during the pre-processing, dyeing, printing and other processing processes. As for the setting process, it is to properly set the tension of the burner equipment of the tenter setting machine, so that the fabric is heated to the required temperature and maintained for a certain period of time under the proper tension condition, so that the fiber molecular chain can be readjusted in the new position. Then let it cool down at a certain speed, so as to fix the state of the fabric after the heat treatment. In other words, the use of the burner equipment of the stenter setting machine can cleverly eliminate the original wrinkles on the fabric and prevent the generation of new wrinkles. In the transmission system of the low-temperature combustion machine, the whole machine mainly consists of 7 synchronous transmission units, 4 circulating fans (8-chamber drying room) and 2 exhaust fans. About the technical requirements of the stenter setting machine burner: First of all, in the actual operation process, in order to ensure a good processing effect, the speed and position of the left and right main chains of the stenter setting machine burner equipment need to be synchronized to avoid fabric weft deviation. Secondly, 10-segment width control, the amplitude modulation accuracy should be controlled within ±2mm. In addition, in the process of processing the burner of the stenter setting machine, it is also necessary to strictly control its temperature and tension in accordance with the process requirements. This is because temperature and tension are two key parameters in the shaping process. Reasonable control of these two parameters will help improve the treatment effect of the burner of the stenter setting machine. ! If you are interested in low temperature burners, please contact us for a quote!