Low calorific burner

Low calorific value burner is divided into coke oven gas burner, blast furnace gas burner, origin furnace gas burner!

Coke oven gas burner

Coke oven gas burner using innovative combustion technology, with reference to international and domestic standards manufacturing mechatronics automatic split combustion coke oven gas burner, coke oven gas burner is widely used in steam boilers, hot water boilers, thermal oil furnaces, lithium bromide direct air conditioning units combustion, Air heating ovens and other industrial ovens.

The coke oven gas burner power coverage is wide, suitable for boilers with tonnage from 1t / h to 40t / h.

According to the requirements corresponding not for conversion can be adapted to high temperature combustion air below 250 ℃.

Features of Coke Oven Gas Burner :

Due to the low calorific value of coke oven gas, and most of it has not been purified or processed incompletely, therefore, the gas contains coal tar, dust and other substances that easily clog the pipeline, therefore, when using coke oven gas, a conventional burner cannot achieve long-term continuous operation .MTG / J series coke oven gas burner is designed for low coke oven gas heating value, low gas supply pressure, high impurity content and special burner, not only maintains the integrated automatic burner combustion stability, high safety performance, but also has coke oven gas resources that characteristics can be fully and safely used, is the use of coke oven gas excellent products.

Fuel adaptation: 2200kcal / Nm3≤Gas calorific value≤4500kcal / Nm3.

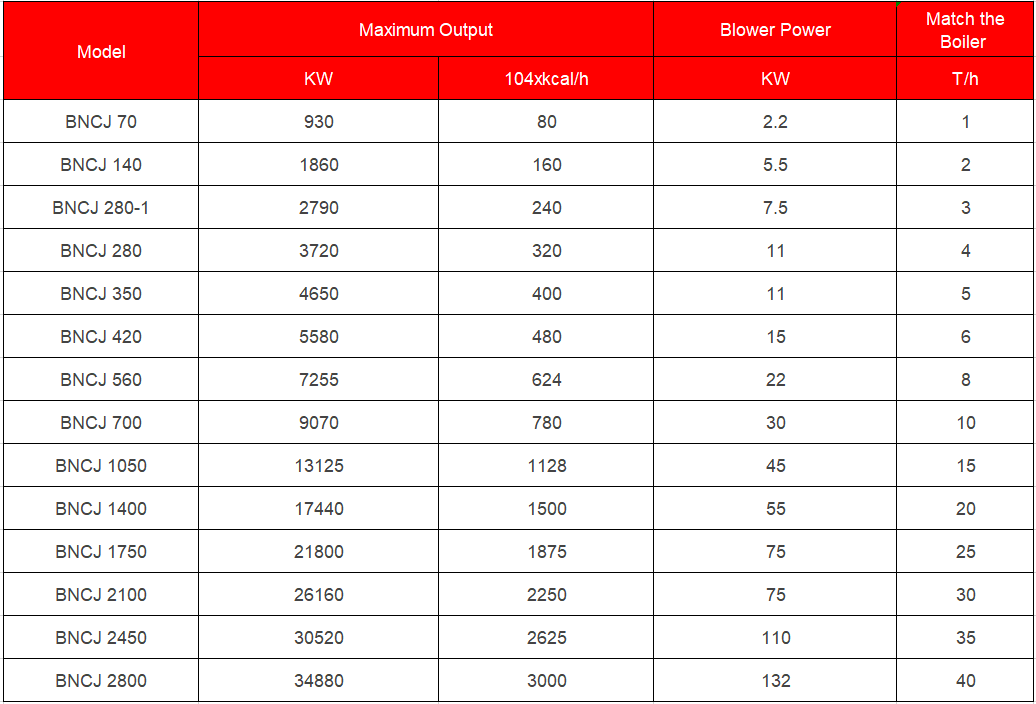

Coke Oven Gas Burner Parameters :

* Suitable for the combustion chamber, the back pressure is not more than 1500pa, the altitude is less than 500m of the environment.

* When the environment changes, the fan is adjusted according to the back pressure and the installation height of the equipment.

Performance characteristics :

● Fully automatic operation, suitable for a wide power range

● Protection against gas pressure, protection against air pressure

● Furnace pre-purge

● Safe flame control system

● When the burner is stopped, the damper automatically closes

● Double gas shut-off valve, automatic leak detection of a group of gas valves

● Electronic proportional control system Siemens LMV (optional)

● Flue gas oxygen feedback adjustment, adapts to the calorific value in a certain range of variations in the Gas, in order to achieve energy-saving sliding two-stage or modulating control.

Blast furnace gas burner

Blast furnace gas burner :

Based on the characteristics of low blast furnace gas calorific value, difficult ignition, easy fire shutdown, slow reaction rate, etc., the company has designed and manufactured a blast furnace gas burner using three-stage combustion, which is divided into three-stage combustion, i.e. the first ignition of high-calorific fuel. capacity (for example, natural gas, liquefied gas) and in the composition of gas fuel with a high calorific value. A heat-resistant and stable combustion chamber is arranged inside the burner, gas and air are mixed in an annular weld with a vortex plate after ejection combustion to ensure the stability and adequacy of combustion.

Fuel adaptation: 600kcal / Nm3≤Gas calorific value <1100kcal / Nm3.

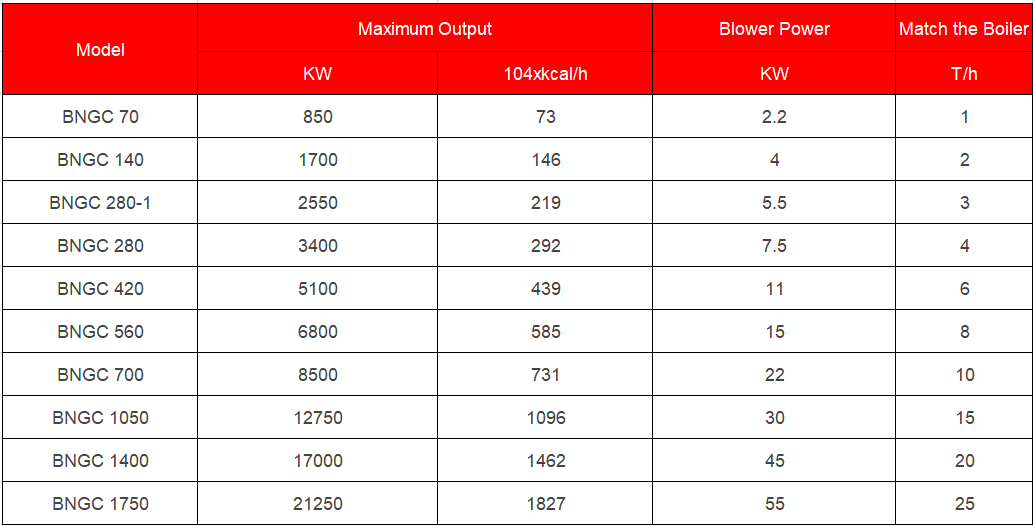

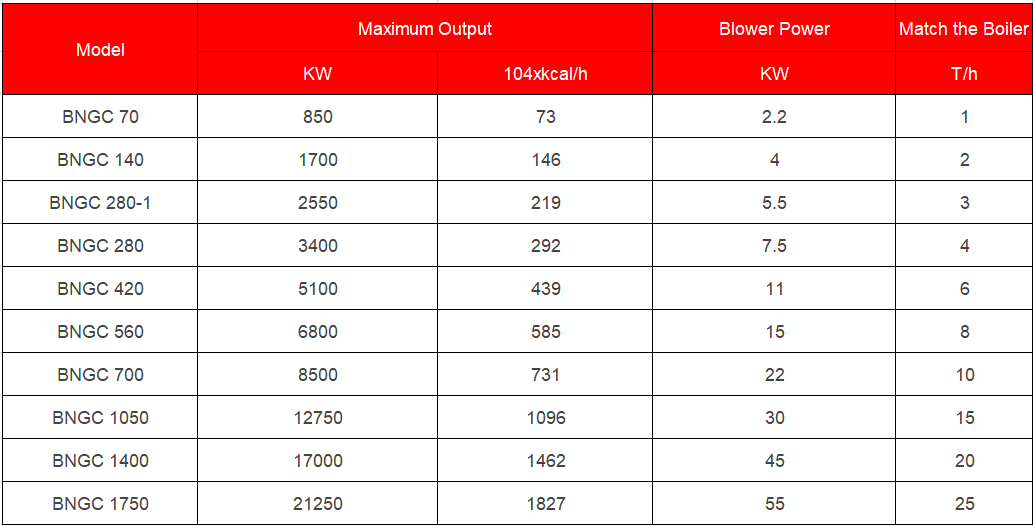

Blast Furnace Gas Burner Technical Parameters :

Gas consumption is calculated based on the calorific value of blast furnace gas 800 kcal / nm3.

Above 500 m, the wind and fan power must be re-considered.

Performance characteristics :

L Fully automatic operation, suitable for a wide power range

l protection against high and low gas pressure

l air pressure protection

L Double gas shut-off valve, automatic leak detection of a group of gas valves

L Safe flame control and fire protection control

L Automatic Pre and Post Purge

l The throttle valve closes automatically when the burner stops

L Siemens LMV Electronic Proportional Control System (optional)

L flue gas oxygen feedback adjustment, adapts to the calorific value in a certain range of gas changes, to achieve energy saving (optional)