- E-mail: [email protected]

- POffice Add:13th Floor, Building 16, National University Science Park,Zhengzhou,Henan,China

- Factory Add:No. 33 Xinhua Road,Xinmi,Henan,China

- +0086-156-3978-1876

- [email protected]

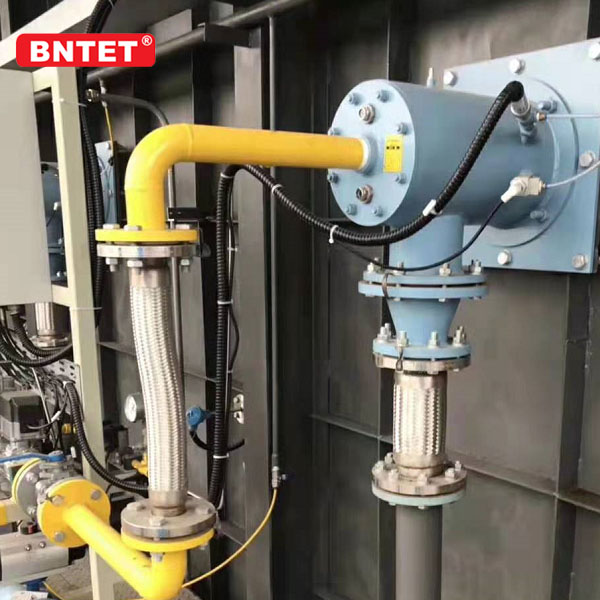

Tenter setting machine burner Purpose: Tenter setting machine burner for warp knitting, weft knitting, chemical fiber fabric heat setting It can also be used for heat setting of various fabrics such as coating, wool, cotton and polyester. Car type: left-handed, right-handed (customized by user). Working width: 800-3200 (customized by customer). Heat source: oil heating, oil heating furnace for main drying and 400,000 kcal/hour. Spray style: small cycle The mesh staggered strong jet wind speed is 10m/s. Planned speed: 0~80 m/min. Weight of the whole machine: 40 tons. Temperature: 100~180 degrees Usage: This machine is suitable for all kinds of carpets, non-woven fabrics, artificial leather, etc. Glue processing punishment. The basic principle: Adopt natural latex, butadiene rubber to foam, and then use the original configuration to deal with the anti-slip and elegant results on the back of the carpet. Model: Model 2000 and Model 4000, non-standard production lines can be planned according to customers if there are special process requirements. The working principle of the setting machine feeds the unshaped cloth from the edge stripper into the machine, and the machine automatically hangs the two ends of the cloth on the needle plate. The two ends of the needle plate enter the oven with the step of the machine, and the oven is heated by electricity. , The fan blows the air, and the constant temperature oven with several different temperature sections in succession enters the tail end and after cooling to remove static electricity, the swing falls into the cloth car, and a crisp and elegant cloth is obtained. The stenter setting is usually used for polyester and other chemical fiber products! If you are interested in low temperature burners, please contact us for a quote!

Tenter setting machine burner Purpose: Tenter setting machine burner for warp knitting, weft knitting, chemical fiber fabric heat setting It can also be used for heat setting of various fabrics such as coating, wool, cotton and polyester. Car type: left-handed, right-handed (customized by user). Working width: 800-3200 (customized by customer). Heat source: oil heating, oil heating furnace for main drying and 400,000 kcal/hour. Spray style: small cycle The mesh staggered strong jet wind speed is 10m/s. Planned speed: 0~80 m/min. Weight of the whole machine: 40 tons. Temperature: 100~180 degrees Usage: This machine is suitable for all kinds of carpets, non-woven fabrics, artificial leather, etc. Glue processing punishment. The basic principle: Adopt natural latex, butadiene rubber to foam, and then use the original configuration to deal with the anti-slip and elegant results on the back of the carpet. Model: Model 2000 and Model 4000, non-standard production lines can be planned according to customers if there are special process requirements. The working principle of the setting machine feeds the unshaped cloth from the edge stripper into the machine, and the machine automatically hangs the two ends of the cloth on the needle plate. The two ends of the needle plate enter the oven with the step of the machine, and the oven is heated by electricity. , The fan blows the air, and the constant temperature oven with several different temperature sections in succession enters the tail end and after cooling to remove static electricity, the swing falls into the cloth car, and a crisp and elegant cloth is obtained. The stenter setting is usually used for polyester and other chemical fiber products! If you are interested in low temperature burners, please contact us for a quote!