- E-mail: [email protected]

- POffice Add:13th Floor, Building 16, National University Science Park,Zhengzhou,Henan,China

- Factory Add:No. 33 Xinhua Road,Xinmi,Henan,China

- +0086-156-3978-1876

- [email protected]

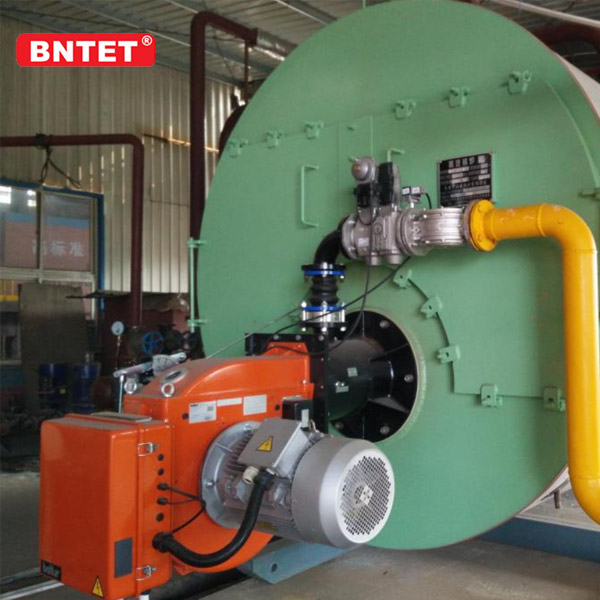

To The burner is a common ignition tool when burning the boiler. The following points must be paid attention to when using the burner. First of all, we must clean up the dust inside the burner before starting. Second, we can turn on the power of the equipment to check whether the circuit is operating normally. After starting, pay attention to maintain the power of the burner, and not cause the current to increase or decrease. Adjust the air supply gear to a small value, put in a proper amount of base material, and start the fire formally, open the furnace door lightly to supply air, close the furnace door, start the feeding system, and gradually adjust the air supply gear to an appropriate amount. The feeding speed and air supply volume should be gradually increased, and it should not be accelerated too fast. There should be 2-3 minutes for the furnace temperature to rise normally. How it works Feeding quick freezing takes 30-80 as the conventional dosage, the fastest speed of the burner does not exceed 100, and the slowest speed cannot be lower than 20. The air volume can be equipped with the highest grade, but the exhaust situation of the chimney should be observed at any time. The standard of speed. Observe water temperature changes from time to time and adjust the drainage volume to achieve safety and conservation; add fuel appropriately according to the user's raw material consumption law to ensure the normal operation of the equipment; adjust the intermittent feeding volume in the heat preservation stage according to the change in product energy consumption. Feeding is stopped 15 minutes earlier, and the fan keeps running. (It has been set on the control panel) Close the material isolation valve; turn off the power, stop the fan, gently open the upper and lower two furnace doors, and maintain a proper amount of natural air to minimize the furnace carbon deposit. The fuel must use pure wood pellets of c6-8mm biomass, do not use pellets and too much pellet fuel. Prevent iron swords from entering the material box when feeding! If the equipment is damaged due to poor fuel or iron objects entering the material box, it will not be covered by the warranty. To If you are interested in gas oil burners, please contact us for a quote!