- E-mail: [email protected]

- POffice Add:13th Floor, Building 16, National University Science Park,Zhengzhou,Henan,China

- Factory Add:No. 33 Xinhua Road,Xinmi,Henan,China

- +0086-156-3978-1876

- [email protected]

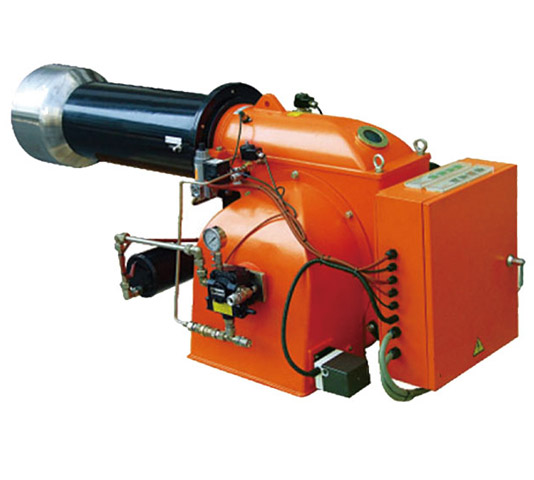

Heavy oil burners are also called tire oil burners, waste oil burners, residual oil burners, etc.

The technical characteristics of heavy oil burners:

1. The flame stabilizer is used to maintain a stable vortex circulation at the root of the flame and reduce the rotation of the internal air, so that the primary air volume can be reduced by half.

2. A flame holding hood is used to prevent the heavy oil entrained in the airflow from perging arbitrarily to produce a brake-like effect." The flame shape history is reasonable to avoid high temperature at the kiln head and prolong the service life of the kiln head guard iron.

3. The external clean air has an intermittent rectangular straight air jet, and it is changed to an annular gap jet after reaching the front of the burner. At the same time, the area of the annular gap is increased to lengthen the flame and increase the average temperature in the kiln.

4. Swirl blades are installed at the front end of the inner air duct, 2cm away from the front end of the outer air cylinder wall, which play a role in gathering the flame and avoid the high temperature of the kiln head. The first handle of the burner can be adjusted. The position of the swirling blade is positioned at the 6” position of the scale when leaving the factory. The adjustment range is 0} 6cm. There is no negative value. The internal wind swirl can only be pulled back to lengthen the flame

5. The center wind blows the high-temperature gas around the nozzle and pushes it back, not only cooling the interior of the nozzle, but also cooling the end face, thereby protecting the burner head and extending the life of the burner.

Previous: Pre:Applicable fuel for rotary kiln burner

Previous: Pre:Applicable fuel for rotary kiln burner